Hi All! Read through a few posts, but still cant quote find an answer for my issue.

To start I have a 2015 Equinox with a 2.4L with 140K miles.

Last year I had some timing chain noise on start up. Brough it to my mechanic and he said low on oil. Just over 2qts in engine. Assumed I did a bad oil change at home and counted quarts wrong and was low as there are no obvious signs of oil leaks or oil burning. Did a oil chance, and all was well.

The next few oil changes I did at 3k miles each. Hard for me to track how much come out cause it dumps into a 20qt container.

About 9 months later we are driving down the highway and engine lost power for a split second then regained it then continues driving fine for the last mile to the exit. At the exit it was idling ROUGH. Made it another mile to the gas station and added 3 qts of oil. I KNOW my last oil change wasn't counted wrong as I specifically bought a 5qt oil jug instead of my 6 gallon box I normally buy. This is when i realized I really needed to watch oil level through oil changes. This is also the time the CEL came on for P0016 and P0017. However in the coming weeks the engine just kept randomly clunking at idle(guides breaking apart) and would return to normal. Over time engine became sluggish.

Finally got into the engine to replace Balance chain, guides, tensioner and timing chain, guides, tensioner, Phasers and solenoids, gaskets(All items ACDELCO). I did all this. Took pictures of my timing marks after checking for idk.... 11 times lol All is good. Engine has significantly more power, not 100% though. And idle smooth as can be. But. I have P0017 still. Upon opening cover I found all large pieces of the front guide, so don't think I have any pieces in the pickup. Upon removal of the old solenoids, the center screens had a layer of plastic shavings(likely from the front guide being ground away from chain). One other thing I made note of., but not 100% if its an issue, is the reluctor ring on the exhaust CAM. I read this can possibly slip according to a TSB(however never found anyone ever saying they did have one slip), and cause your exhaust to be read as if it were not timed right. I have attached a picture of the ring to show what I am talking about. The last Lobe on the camshaft is inline with a "seam" line from manufacturing, which looks like its supposed to be offset 3ish* counterclockwise from a notch on the ring, where mine looks to be more inline.

Took it all apart again. And re-did timing. Again checked it 17 times this time, have pictures. And still afterwards I have P0017.

After timing chain and computer reset. P0017 is an instant pending code upon restart. And shortly after(few minutes of idle or 1/4 mile drive) it sets and is on.

I went to my mechanic and used his scan tool(Much nicer then mine). We tried to do a cam/crank relearn but would NOT hit fuel cut off. Took a dozen or so computer resets to get the relearn to work and hit fuel cut off. Finally test passed. Still, P0017 returns in same manner.

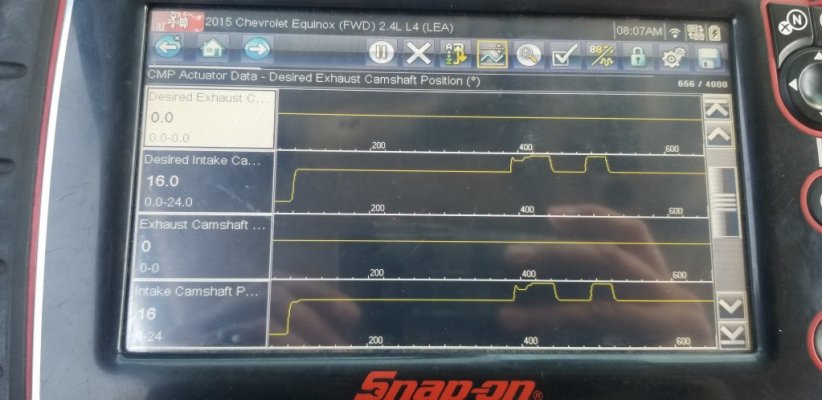

I then went and viewed live data while engine runs. Intake idles around 5* i think. The desire position is 5*, the commanded position is 5* and the actual position is 5*. All is great. The exhaust on the other hand. Desired is at 0*, the commanded is at 0*, and the actual is at 0*. No matter what revving I do, no matter what brake and drive revving I did I could not get exhaust to change. Intake would change constantly but all matched(desired, commanded, actual). So did exhaust, but always 0*. I ran all this date with CEL on and also with resetting CEL, results were the same.

I also ran phaser tests. You can command a phased * and the computer will do it. I didn't have much luck because the computer kicks you out of tests when there is a pending CEL. And being P0017 is pending almost immediately, I have only a few seconds to test. I can command the intake from 0*-25* and it did all of them(5* incriments). The exhaust on the other hand just didn't listen to my commands. I would command 5*. But the computer would not command 5*, it did not desire 5* and was in actual 0*. Almost as if the computer would not take my command at all.

I then ran a valve test. This is an engine off test. Again only have a few seconds as the P0017 is instantly pending upon rest(i think this is a permanent code?). This test just turns the valves on or off. When running these tests on both intake and exhaust, they both seem to be working fine. When I turn valves on, the computer sees them turning on, and same with off.

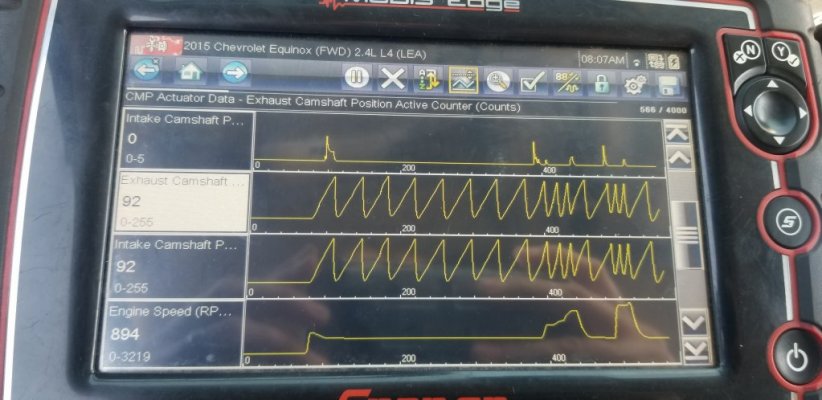

The last thing I can think to add is the position sensors. They both seem to be working fine as well. When the engine is running the scanner can see the counts of each sensor. Counting up to 250, then resetting to 0, and starts over. If comparing intake to exhaust, they should both count equally at the same rate side by side as intake and exhaust spin at same RPM. When viewed side by side and revving engine up and down, the counts are identical. This shows the computer sees the data from the sensors and that both sensors are working perfectly.

My question is. Why is P0017 showing so quick? P0017 is a cam/crank correlation between exhaust cam and crank. This means they are not able to be desirable. However. All my data shows is that is is all desirable. So why is it saying its not? It wants the exhaust cam at 0* and its actually at 0*. If my reluctor ring spun, the engine would show that the exhaust CAM were NOT at 0* like it is currently timed too with the chain, it would show it offset whatever deg the ring was spun too. The computer should be showing me this infor. Again, I have no solid answer as to weather or not my ring spun, but this is the only piece of information that was a grey area for me, but the computer data seems to be proving that it is fine.

I hope someone else has had this issue and can help! If not, more brains is better then 1..... or 3.... Im lost, my mechanic is lost and a friend whos an engineer who worked at GM in the lab that worked on the valve train for these engines is lost too lol I have attached pictures of my timing marks, the reluctor ring with lobe, seam, gap alignment, and a new stock photo to compare. Thank you all!

EDIT: Added snap shots of the scan tool. First shows exhaust and intake position sensor counters side by side. At the beginning its counting consistent at idle. I then rev engine a few times and you can see they both react the same and the counts count quicker. The second picture is showing the computers desired location, along with its actual location and can see that they match.

To start I have a 2015 Equinox with a 2.4L with 140K miles.

Last year I had some timing chain noise on start up. Brough it to my mechanic and he said low on oil. Just over 2qts in engine. Assumed I did a bad oil change at home and counted quarts wrong and was low as there are no obvious signs of oil leaks or oil burning. Did a oil chance, and all was well.

The next few oil changes I did at 3k miles each. Hard for me to track how much come out cause it dumps into a 20qt container.

About 9 months later we are driving down the highway and engine lost power for a split second then regained it then continues driving fine for the last mile to the exit. At the exit it was idling ROUGH. Made it another mile to the gas station and added 3 qts of oil. I KNOW my last oil change wasn't counted wrong as I specifically bought a 5qt oil jug instead of my 6 gallon box I normally buy. This is when i realized I really needed to watch oil level through oil changes. This is also the time the CEL came on for P0016 and P0017. However in the coming weeks the engine just kept randomly clunking at idle(guides breaking apart) and would return to normal. Over time engine became sluggish.

Finally got into the engine to replace Balance chain, guides, tensioner and timing chain, guides, tensioner, Phasers and solenoids, gaskets(All items ACDELCO). I did all this. Took pictures of my timing marks after checking for idk.... 11 times lol All is good. Engine has significantly more power, not 100% though. And idle smooth as can be. But. I have P0017 still. Upon opening cover I found all large pieces of the front guide, so don't think I have any pieces in the pickup. Upon removal of the old solenoids, the center screens had a layer of plastic shavings(likely from the front guide being ground away from chain). One other thing I made note of., but not 100% if its an issue, is the reluctor ring on the exhaust CAM. I read this can possibly slip according to a TSB(however never found anyone ever saying they did have one slip), and cause your exhaust to be read as if it were not timed right. I have attached a picture of the ring to show what I am talking about. The last Lobe on the camshaft is inline with a "seam" line from manufacturing, which looks like its supposed to be offset 3ish* counterclockwise from a notch on the ring, where mine looks to be more inline.

Took it all apart again. And re-did timing. Again checked it 17 times this time, have pictures. And still afterwards I have P0017.

After timing chain and computer reset. P0017 is an instant pending code upon restart. And shortly after(few minutes of idle or 1/4 mile drive) it sets and is on.

I went to my mechanic and used his scan tool(Much nicer then mine). We tried to do a cam/crank relearn but would NOT hit fuel cut off. Took a dozen or so computer resets to get the relearn to work and hit fuel cut off. Finally test passed. Still, P0017 returns in same manner.

I then went and viewed live data while engine runs. Intake idles around 5* i think. The desire position is 5*, the commanded position is 5* and the actual position is 5*. All is great. The exhaust on the other hand. Desired is at 0*, the commanded is at 0*, and the actual is at 0*. No matter what revving I do, no matter what brake and drive revving I did I could not get exhaust to change. Intake would change constantly but all matched(desired, commanded, actual). So did exhaust, but always 0*. I ran all this date with CEL on and also with resetting CEL, results were the same.

I also ran phaser tests. You can command a phased * and the computer will do it. I didn't have much luck because the computer kicks you out of tests when there is a pending CEL. And being P0017 is pending almost immediately, I have only a few seconds to test. I can command the intake from 0*-25* and it did all of them(5* incriments). The exhaust on the other hand just didn't listen to my commands. I would command 5*. But the computer would not command 5*, it did not desire 5* and was in actual 0*. Almost as if the computer would not take my command at all.

I then ran a valve test. This is an engine off test. Again only have a few seconds as the P0017 is instantly pending upon rest(i think this is a permanent code?). This test just turns the valves on or off. When running these tests on both intake and exhaust, they both seem to be working fine. When I turn valves on, the computer sees them turning on, and same with off.

The last thing I can think to add is the position sensors. They both seem to be working fine as well. When the engine is running the scanner can see the counts of each sensor. Counting up to 250, then resetting to 0, and starts over. If comparing intake to exhaust, they should both count equally at the same rate side by side as intake and exhaust spin at same RPM. When viewed side by side and revving engine up and down, the counts are identical. This shows the computer sees the data from the sensors and that both sensors are working perfectly.

My question is. Why is P0017 showing so quick? P0017 is a cam/crank correlation between exhaust cam and crank. This means they are not able to be desirable. However. All my data shows is that is is all desirable. So why is it saying its not? It wants the exhaust cam at 0* and its actually at 0*. If my reluctor ring spun, the engine would show that the exhaust CAM were NOT at 0* like it is currently timed too with the chain, it would show it offset whatever deg the ring was spun too. The computer should be showing me this infor. Again, I have no solid answer as to weather or not my ring spun, but this is the only piece of information that was a grey area for me, but the computer data seems to be proving that it is fine.

I hope someone else has had this issue and can help! If not, more brains is better then 1..... or 3.... Im lost, my mechanic is lost and a friend whos an engineer who worked at GM in the lab that worked on the valve train for these engines is lost too lol I have attached pictures of my timing marks, the reluctor ring with lobe, seam, gap alignment, and a new stock photo to compare. Thank you all!

EDIT: Added snap shots of the scan tool. First shows exhaust and intake position sensor counters side by side. At the beginning its counting consistent at idle. I then rev engine a few times and you can see they both react the same and the counts count quicker. The second picture is showing the computers desired location, along with its actual location and can see that they match.

Attachments

Last edited: